Ob chav nyob rau theem cutter compactor rov ua pelletizing kab

Cov lus qhia

| Phiaj ua cov khoom siv rov ua dua tshiab | HDPE, LDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, ABS | |||||

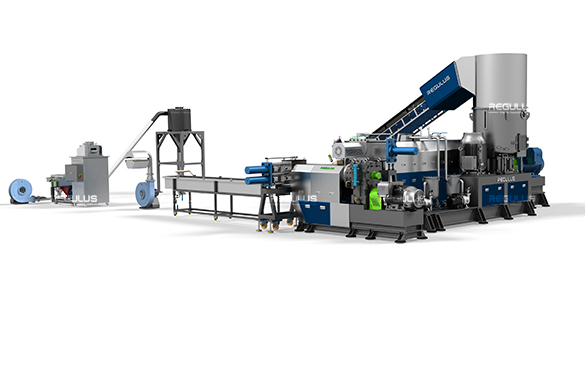

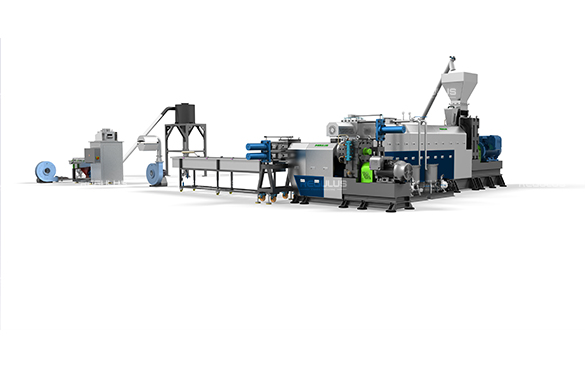

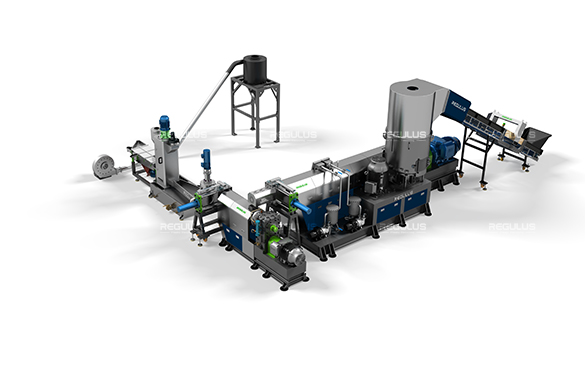

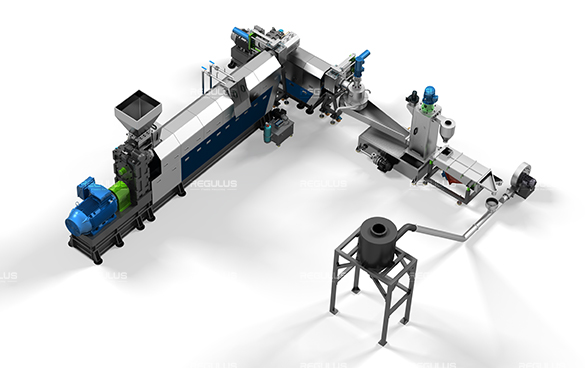

| Muaj pes tsawg leeg | Siv conveyor, txiav compactor, tib ntsia hlau extruder, pom,Pelletizer, Dej txias ntaus ntawv, lub cev qhuav dej, cov kiv cua ntxuam, khoom lag luam silo. | |||||

| Cov Khoom Siv Ntawm Ntsia Hlau | 38crmoala (Sacm-645), Bimetal (yeem) | |||||

| L / d ntawm ntswj | 28/1, 30/1, 33/1, (raws li tus yam ntxwv ntawm kev rov ua dua tshiab) | |||||

| Rhaub ntawm lub teb | Tej hub rhaub lossis deb-infrared rhaub | |||||

| Cua txias ntawm lub chim | Cua Txias ntawm cov kiv cua los ntawm lub tshuab tawg | |||||

| Pelletizing hom | Dej-ntiv nplhaib pelletizing / Dej-strands pelletizing / nyob rau hauv-dej pelletizing | |||||

| Kev Pabcuam Kev | kev tsim qauv, kev tsim kho Hoobkas, kev teeb tsa thiab cov lus pom zoo, kev ua haujlwm | |||||

| Tshuab Qauv | Lub ntsiab lus | L / d | Ib sab ntsia hlau extruder | |||

| Qho loj hnyav | Lub cev muaj zog | Ntsia Hlau taub | Extruder Tsav | Tso Rau Muaj Peev Xwm | ||

| (Liter) | (kw) | (hli) | (kw) | (kg / h) | ||

| XY-85 | 350 | 37 | 85 | 28 | 55 | 150-250 |

| 10 | 22 | |||||

| XY-100 | 500 | 55 | 100 | 28 | 90 | 250-350 |

| 10 | 30 | |||||

| XY-130 | 850 | 90 | 130 | 28 | 132 | 450-550 |

| 10 | 45 | |||||

| XY-160 | 1100 | 110-132 | 160 | 28 | 185 | 650-800 |

| 10 | 55 | |||||

| XY-180 | 1500 | 185 | 180 | 28 | 250-280 | 900-1100 |

| 10 | 90 | |||||

CUTTER COMPACTORAS Yas Recycling Pelletizing System

Txoj kev sib sau ua ke thiab pelletizing system sib txuas ua haujlwm ntawm crushing, compacting, yas thiab pelletizing rau ib kauj ruam. Thov nyob rau hauv cov plastics recyclng thiab pelletizing txheej txheem. ACSHS TM system yog ib qho kev ntseeg siab thiab kev ua tau zoo rau cov duab dhos, cov hnab ntim khoom, hnab ntim khoom thiab ua npuas dej rau lub tshuab ua lag luam siab. Nws tuaj yeem muab cov zis ntau dua tab sis nrog qis zog siv cov lus sau tseg. Daim Ntawv Thov: PE, PP, PS, ABS, XPS, EPS, Pvb.

Kev pub mis

Raws li kev tsim qauv, cov yas scraps xws li zaj duab xis, filament, Raffias conveyed rau hauv chav sau los ntawm txoj siv conveyor; Txhawm rau coj yob 'scraps, yob haulling tawm ntaus ntawv yog ib txoj kev noj haus. Lub cev muaj zog ntawm CONVEYOR siv thiab Hauling ntaus sib koom tes nrog inverter. Kev pub zaub mov ceev ceev ntawm conveyor siv lossis muab kaw cia yog li tsis tuaj raws li cas lub compactor chav yog.

Crushing thiab cog lus

Compactor tau nruab nrog cov khoom siv huab cua. Nrog rau kev ua haujlwm ntawm rotor riam thiab cov khoom siv yuav maj mam nce tom qab kev sib txhuam, thiab hmoov av rau saum npoo ntawm raw khoom yuav ntab mus rau saum lub compactor. Cov cuab yeej tuaj yeem tshem tawm cov dej noo thiab hmoov av, uas yuav zam kom tsis txhob siv hluav taws xob ntxiv los daws cov cua sov ua ntejKev pub mis.

Lub rotatory siav ntawm compactor

Cov hniav sib hloov thiab tsau hniav txiav txiav cov khoom rau hauv cov flakes me me. Qhov kev sib txhuam cua sov tsim los ntawm cov cua ntau heev sib hloov yuav ib-cua sov thiab ntsws cov flakes.

Ib sab ntsia hlau extruder

Peb cov qauv tshwj xeeb tib ntsia hlau extruder maj mam muab cov yas thiab homogenizes cov khoom siv. Peb cov hlau-hlau Extruder muaj cov tshuaj tiv thaiv zoo heev tiv thaiv corrosion tiv thaiv, hnav tiv taus ntev thiab ntev.

Lub Tshuab Nqus Tsev Zaum Ob Chav

Nrog ob lub tshuab nqus tsev degassing ib cheeb tsam, tsis muaj suab paj nruag thiab noo noo yuav tau muab cov khoom siv ua tau zoo los txhim kho cov granules zoo, tshwj xeeb tshaj yog tsim nyog rau cov ntaub ntawv luam hnyav.

Phaj Hom Screen Charger

Cov phaj hom lim yog ua hauv cov hom nruam nrog ob daim hlau lim. Muaj tsawg kawg yog ib lim ua haujlwm thaum lub vijtsam yog hloov pauv cov rhaub kom zoo nkauj rau cov cua sov sib xws thiab ruaj khov

Tsis muaj-nres piston hom lim

1.A ib txwm muaj-phaj / piston ob-chaw nres tsheb screen hloov chaw lossis tsis nres ob lub chaw nres tsheb tuaj yeem ntsia rau ntawm lub taub hau extruder los qhia kev ua kom pom tseeb.

2.Nlong npo Lub neej, qis Screen hloov zaus: Ntev lim lub neej ntev uas muaj thaj chaw lim loj.

3. Yooj yim siv thiab tsis muaj hom nres: Cov kev hloov pauv yooj yim thiab tsis tas yuav tsum nres lub tshuab khiav.

4. Siv cov haujlwm ua haujlwm tsis tshua muaj nqi.

Pluaj Mould

Lub Rub Pwm yog siv dav, thiab cov ntaub ntawv nyoos xws li PP, PE, Abs, Tsiaj, thiab lwm yam kev lag luam

Yas Granulation Hlau Txias Tank

1.Txoj kev sib txuas kev co sab cib sib txuas nrog kab rov tav-centrifugal de centrifatering tam sim no kev ua tiav qhuav pellets thiab qis zog siv zog.

2. Sib xum sieves: Cov siev yog ntsia thiab tsau los ntawm cov ntsia hlau es tsis txhob vuam, yog li koj tuaj yeem hloov cov sieves tau yooj yim yav tom ntej.

Yas Granulation Hlau Txias ntxuam qhov system

Siv rau tshem tawm cov dej noo los ntawm cov yas zawm

Yas Granulation Kab Txiav System

Siv rau txiav cov txheej txheej yas ua kom cov khoom tawg

Vibrating npo

Siv los cais qhov loj me ntawm cov yas